PLASMA CUTTING SYSTEMS

WITH MORE PERFORMANCE & ROI

US NAVY VETERAN OWNED BUSINESS IN OPERATION SINCE 2001

Trust the brand that has been

in business for over 25 years.

Choose your table size, material type and thickness.

We’ll get you a quote within 24 hours!

Build YOUR Machine Here

Fill out this form and we’ll get you your custom quote to you shortly.

Discover our plasma

cutting options.

Click on the machines below to learn more!

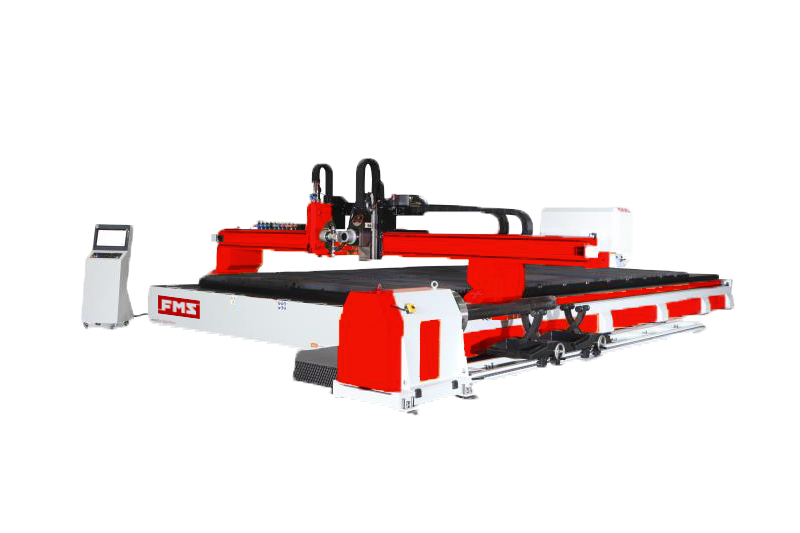

About our FMS Plasma Tables

Plasma cutting is the process of cutting through conductive materials (metals like steel, aluminum, brass, and copper, for example) using an accelerated jet of hot plasma. The process takes place by blasting a compressed gas, such as oxygen or air, from a nozzle at high speed towards the metal to be cut. An electrical current is then shot through the gas, creating an electrical arc within the gas.

This process creates a completed electrical circuit from the nozzle to a grounding clamp, and this conductive channel of plasma is capable of producing temperatures high enough to melt metal. The combination of speed and temperature allow the plasma flame to melt and cut directly through the metal.

Plasma cutting is a high-speed way to easily cut through thick and thin metals alike. Because the plasma cutter forms a hyper-localized plasma cone, it is also an effective method of cutting through curved or angled profiles, such as tubes and beams.